Fort Lauderdale Epoxy Flooring

Over the years floor logic has acquired nothing but the best and latest polishing equipment, diamond technology and dustless vacuum systems to keep up with the growing demands and deliver the highest quality.

A FLEXIBLE SOLUTION FOR POLISHED CONCRETE & EXPOXY

Epoxy floor coatings are something you may have heard of, but did you know about their benefits? These floors offer many benefits, such as easy upkeep and a reduction in dust and cement particles. Epoxy floors are great for homeowners new and old. Floor Logic can help you find an epoxy floor for your commercial or residential building. Contact us today! We are South Florida’s #1-rated flooring company. Learn more about epoxy coatings and their benefits for your home. It’s a great choice for many rooms and applications such as kitchens, bathrooms, commercial garages, and more.

EXPERIENCE & KNOWLEDGE

Epoxy flooring’s greatest benefit is its durability. Epoxy flooring will not chip, crack, peel or peel and can last for many years. Although there are some disadvantages to this flooring, they are far more beneficial than the ones it offers. An epoxy floor’s slippiness, especially when wet is one of its biggest drawbacks. However, you can make it safer for your family and yourself by applying an anti-slip coating.

Epoxy floors also have a great aesthetic benefit. Epoxy floors can improve the look of any room and can also be cost-effective for high-traffic areas. The floor is durable and can withstand all kinds of traffic. They are also easy to maintain, making them a great choice for high-traffic areas. Because of their durability, they are easily customizable to fit any style. You can also find decorative and patterned flooring.

Epoxy is also resistant to heat. It can withstand heat up to a temperature of 200 degrees Fahrenheit once it has dried. It will wear faster than an epoxy refresher if your floor is exposed to high traffic. It is also easy to repair scratches or other damage, making it an excellent choice for commercial locations. It’s also less expensive than other flooring types and can be easily fixed in the event of an accident.

MEDIA GALLERY

KEY BENEFITS

- Remove existing coatings (for thick coatings, use a 16- or 20-grit diamond abrasive or more aggressive tool specifically for coating removal, such as PCD’s optional)

- Seal cracks and joints with an epoxy or other semi-rigid filler.

- Grind with a 30- or 40-grit metal-bonded diamond.

- Grind with an 80-grit metal-bonded diamond.

- Grind with a 150-grit metal-bonded diamond (or finer, if desired).

- Apply a chemical hardener to densify the concrete.

- Polish with a 100- or 200-grit resin-bond diamond, or a combination of the two. (HONED)

- Polish with a 400-grit resin-bond diamond. (LOW GLOSS)

- Polish with an 800-grit resin-bond diamond. (MEDIUM GLOSS)

- Optional: Apply a stain guard to help protect the polished surface and make it easier to maintain.

Microtopping for Concrete Flooring

What is Ghosting?

Floor Logic offers many design options for polished concrete, including coloring with dyes. If you’re floor was previously tiled, polishing may result with a ghosting effect.

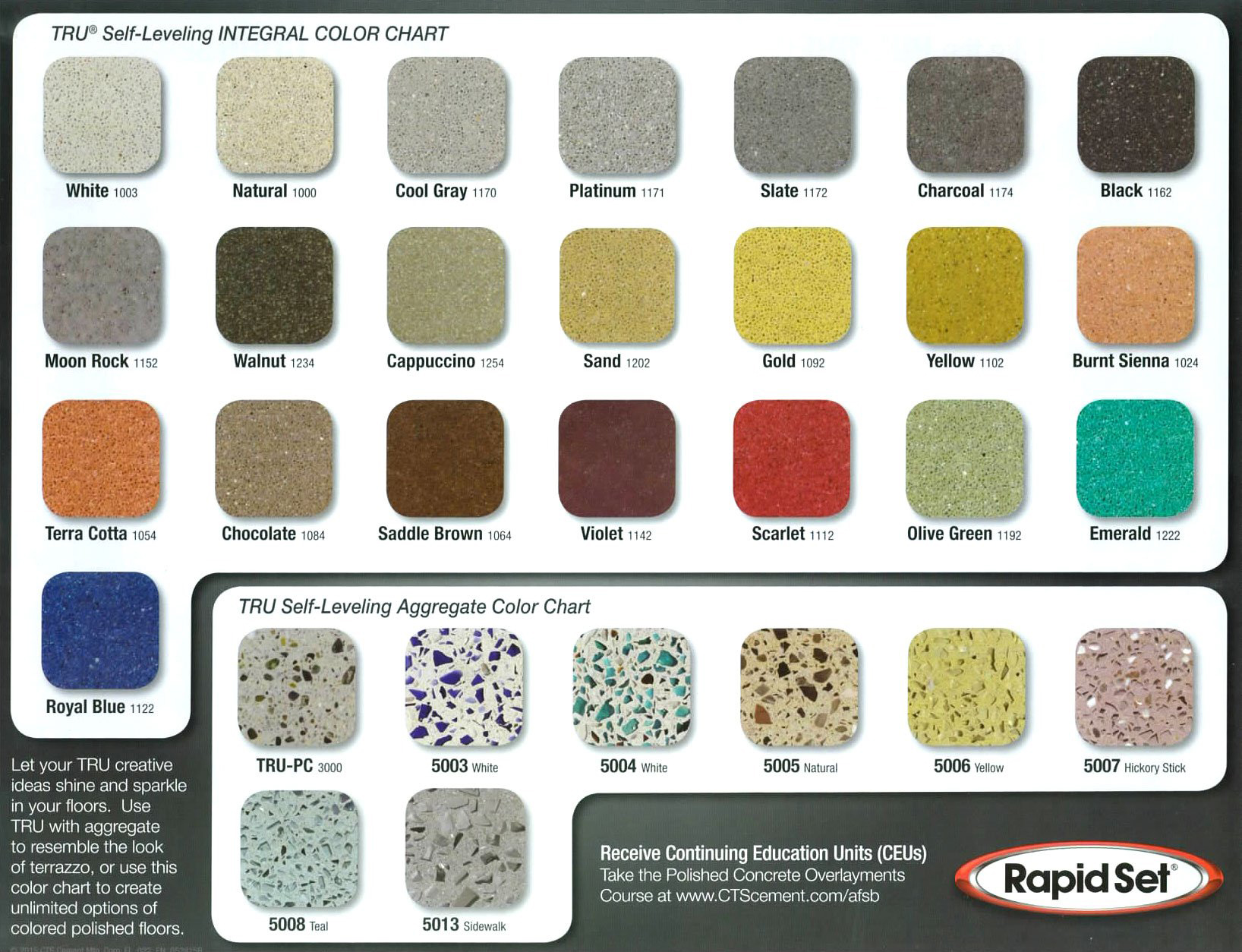

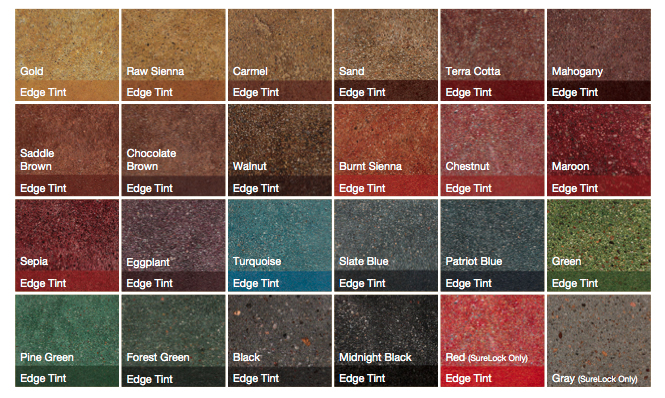

Color Options

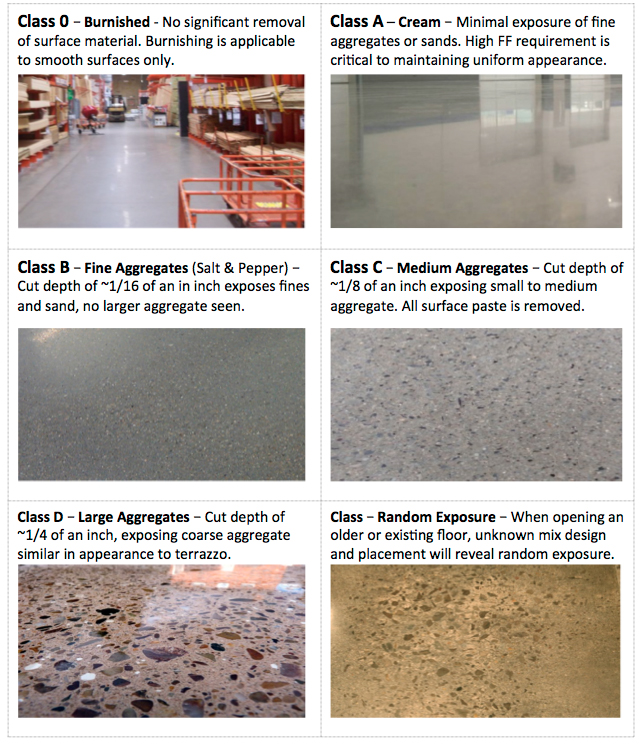

Finishing Options

Polished Overlays

With minimal maintenance and beautiful high-gloss finish, polished concrete floors are becoming the new superstars of the decorative concrete flooring world, especially in high-profile retail, commercial settings and even homeowners. Although most existing concrete slabs can be polished, some have flaws, such as spalled areas, carpet tack holes, staining from previous glued down flooring and extensive patchwork, which would still show through after polishing. And in terms of decorative options, existing polished floors are limited to the application of topical color.

To meet the demand for an aesthetically pleasing solution for polishing imperfect concrete floors, more and more contractors are now installing polished overlays as an economical alternative.

It is essential to properly prepare the epoxy floor before you apply it. To make concrete more pliable for adhesion, we clean it thoroughly. We use a high quality roller to ensure adhesion. Low-quality rollers can cause the floor to crack. The final coat should be applied after the floor has cooled for 24 hours. Before applying the final coat, any holes or uneven surfaces must be filled. We also fill any holes prior to applying the final coat.

Antistatic floors are another option. Self-levelling epoxy flooring is another option. It can be applied in a thickness of 1mm to 3mm. The liquid material creates a seamless, non-slip surface. Antistatic epoxy flooring on the other hand provides an electrostatic-free finish and protects sensitive equipment from electric shocks. These epoxy floor coatings are suitable for both residential and commercial applications. Antistatic epoxy flooring is a great choice if you are looking for a durable, seamless coating.

COLOR & FINISH OPTIONS