POLISHED CONCRETE

Over the years floor logic has acquired nothing but the best and latest polishing equipment, diamond technology and dustless vacuum systems to keep up with the growing demands and deliver the highest quality.

A FLEXIBLE SOLUTION FOR POLISHED CONCRETE & EXPOXY

Polished concrete is fast becoming the ultimate environmentally friendly no-wax flooring option. With Floor Logics polishing equipment and techniques, grinding concrete floor surfaces, whether new or old, to a high-gloss finish that never needs waxes or coatings. Factor in the superior durability and performance of concrete, and it’s no wonder why more retail, warehouse, and office facilities are opting for polished concrete flooring as an alternative to marble, granite, tile, linoleum, or coated concrete. Even homeowners are catching on to the appeal of these smooth, high-luster floors, which can be stained to replicate the look of polished stone.

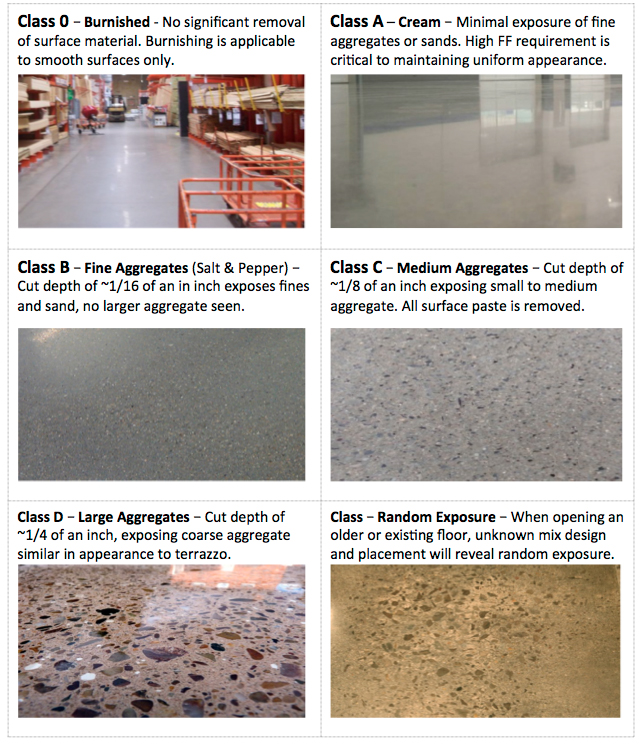

Because polishing is a multistep process, you can choose the level of sheen, from satin to high-gloss, that meets your maintenance and aesthetic requirements. This versatility makes polished concrete an ideal flooring material for a variety of applications.

EXPERIENCE & KNOWLEDGE

Floor logic can polish concrete using wet or dry methods. Although each has its advantages, dry polishing is the method most commonly used in the industry today because it’s faster, more convenient, and environmentally friendly. Wet polishing uses water to cool the diamond abrasives and eliminate grinding dust. Because the water reduces friction and acts as a lubricant, it increases the life of the polishing abrasives. The chief disadvantage of this method is the cleanup. Wet polishing creates a tremendous amount of slurry that crews must collect and dispose of in an environmentally sound manner. With dry polishing, no water is required. Instead, the floor polisher is hooked up to a dust-containment system that vacuums up virtually all of the mess.

Polishing concrete floors requires a great deal of expertise and the use of specialized grinding equipment and industrial grade filtration/vacuum systems that gradually grind down surfaces to the desired degree of shine and smoothness since each job will present different conditions and challenges.

Over the years floor logic has acquired nothing but the best and latest polishing equipment, diamond technology and dustless vacuum systems to keep up with the growing demands and deliver the highest quality.

MEDIA GALLERY

KEY BENEFITS

- Remove existing coatings (for thick coatings, use a 16- or 20-grit diamond abrasive or more aggressive tool specifically for coating removal, such as PCD’s optional)

- Seal cracks and joints with an epoxy or other semi-rigid filler.

- Grind with a 30- or 40-grit metal-bonded diamond.

- Grind with an 80-grit metal-bonded diamond.

- Grind with a 150-grit metal-bonded diamond (or finer, if desired).

- Apply a chemical hardener to densify the concrete.

- Polish with a 100- or 200-grit resin-bond diamond, or a combination of the two. (HONED)

- Polish with a 400-grit resin-bond diamond. (LOW GLOSS)

- Polish with an 800-grit resin-bond diamond. (MEDIUM GLOSS)

- Optional: Apply a stain guard to help protect the polished surface and make it easier to maintain.

Microtopping for Concrete Flooring

What is Ghosting?

Floor Logic offers many design options for polished concrete, including coloring with dyes. If you’re floor was previously tiled, polishing may result with a ghosting effect.

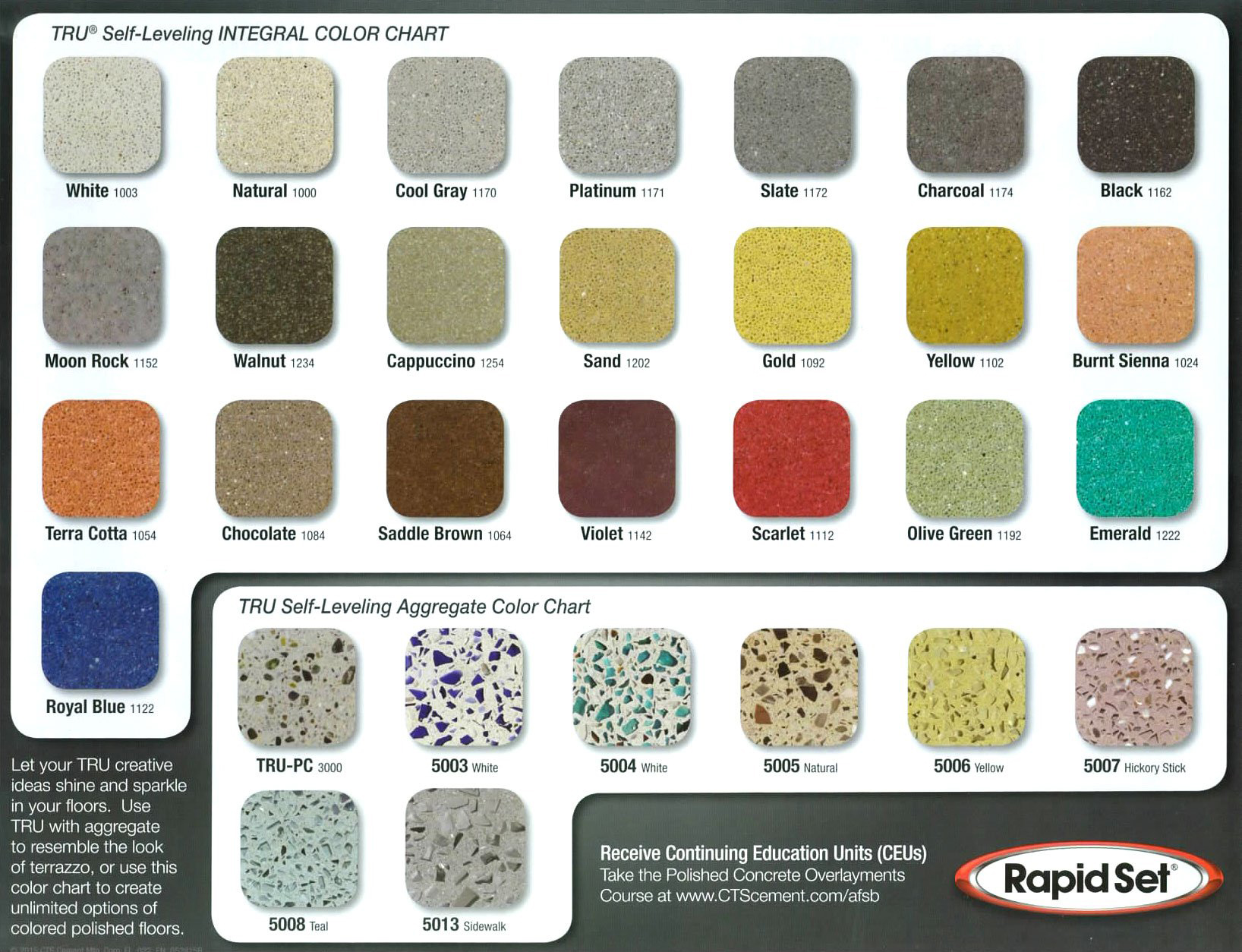

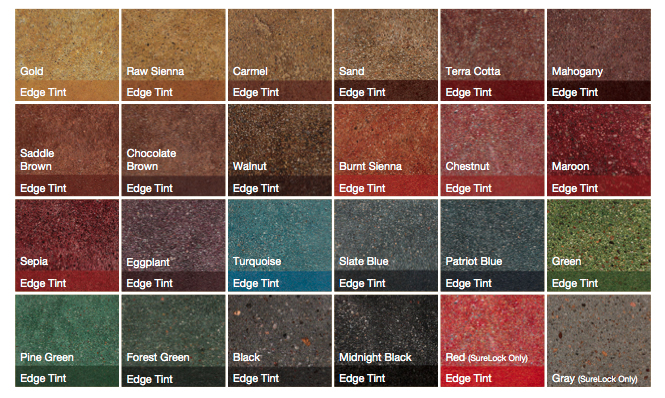

Color Options

Finishing Options

Polished Overlays

With minimal maintenance and beautiful high-gloss finish, polished concrete floors are becoming the new superstars of the decorative concrete flooring world, especially in high-profile retail, commercial settings and even homeowners. Although most existing concrete slabs can be polished, some have flaws, such as spalled areas, carpet tack holes, staining from previous glued down flooring and extensive patchwork, which would still show through after polishing. And in terms of decorative options, existing polished floors are limited to the application of topical color.

To meet the demand for an aesthetically pleasing solution for polishing imperfect concrete floors, more and more contractors are now installing polished overlays as an economical alternative.

Polished overlays are used to cover up problem floors and achieve a perfectly smooth, seamless surface or, the owner wants to enhance an existing floor with decorative saw cuts or get a terrazzo-like finish by seeding the overlay with colored aggregate.

“A polishable overlay will let us provide the polished concrete look without the underlying slab imperfections showing through.

customers appreciate the fast turnaround time of a polished overlay when compared with replacing or patching the existing concrete. “The micro topping can be successfully installed with a fast turnaround time of just 24 hours.

A polished micro topping offers many other attributes as well, “It can easily be treated with color or a decorative coating, it is environmentally friendly, mold and mildew resistant and, economical.

COLOR & FINISH OPTIONS